Last Updated on January 29, 2024 by Asfa Rasheed

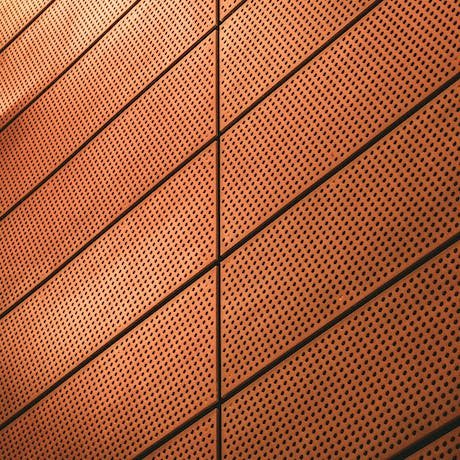

Perforated metal sheeting affords designers and engineers the flexibility to infuse both functionality and aesthetics into a variety of applications, from architectural facades to functional filtration systems. The process of customizing perforation patterns allows for limitless creativity, enabling the creation of distinctive visual effects and precise performance characteristics. As the demand for unique design solutions grows, exploring new patterns in perforated metal sheeting can offer fresh perspectives and competitive edges in a range of industries.

The selection of a perforation pattern goes beyond mere ornamentation; it influences the material’s transparency, strength, and acoustic properties. As such, it is critical to consider the intended application and environmental factors when choosing a pattern. Geometric shapes, abstract designs, and even company logos can be rendered into the metal to fulfill both practical and brand-specific requirements. These custom patterns can also contribute to sustainability goals by optimizing natural lighting and air flow, underpinning the dual function of aesthetics and energy efficiency.

When embarking on a project involving custom perforated sheet metal, the interplay between light and shadow, as well as the sheet’s interaction with its surroundings, must be taken into account. The size, shape, and spacing of perforations determine the transparency of the sheet and its visual impact when viewed from various angles. This attention to detail ensures that the final product not only meets the design specifications but also enhances the overall functionality and allure of the space it inhabits.

Design Essentials for Perforated Metal

The successful design of perforated metal sheeting from a perforated metal manufacturer, hinges on selecting suitable materials, creating effective hole patterns, and ensuring structural integrity.

Choosing the Right Material

The choice of material will significantly dictate the sheet’s performance and aesthetic. Stainless steel is chosen for its strength and corrosion resistance, making it ideal for harsh environments. Aluminum, on the other hand, is lightweight and offers excellent corrosion resistance for aesthetic applications. When durability and cost-effectiveness are paramount, carbon steel may be employed, while for a more decorative touch, copper and brass are prevalent choices.

Optimizing Hole Patterns

Hole patterns must be functional and visually pleasing. A balance between open area and strength is crucial. The open area — the total area of the holes divided by the total area of the sheet — impacts material flow and light penetration. Common patterns include:

- Round holes – Maximizes open area

- Square holes – Provides uniform strength

- Slotted holes – Ideal for filtering

To ensure the pattern aligns correctly across the sheet and to avoid weakened edges, precise calculation of margins and pitch (distance between centers of adjacent holes) is essential.

Considering Structural Integrity

Maintaining the structural integrity of perforated metal sheeting is vital for safety and longevity. The thickness of the material (gauge), the hole size, and the pattern all contribute to the sheet’s overall strength. Proper design ensures that the perforated metal performs under anticipated loads without deforming or failing. Here’s a brief overview:

- Material Thickness: Thicker materials enhance durability.

- Hole Size: Smaller holes typically yield a sturdier sheet.

- Pattern Orientation: Directional patterns should be aligned with load-bearing applications.

Creative Applications

Perforated metal sheeting transcends its industrial origins when applied creatively. It offers aesthetic enhancement, functional benefits, and personalized branding opportunities.

Architectural Beauty

Perforated metal patterns can dramatically transform a building’s facade. Architects often employ geometric shapes or organic forms to create visually stunning effects that also contribute to energy efficiency by modulating light and temperature.

- Examples:

- Geometric: Hexagon, Square, Triangle

- Organic: Leaf, Waves, Abstract Forms

Functional Artistry

In addition to their visual appeal, perforated sheets can be designed to serve specific functions. They can improve acoustics by absorbing sound or be tailored to support environmental goals by facilitating water collection in green building designs.

- Functions:

- Acoustic Improvement: Circular, Slotted Patterns

- Environmental Solutions: Custom Water-permeable Designs

Branding and Customization

Custom perforated patterns allow businesses to infuse their brand identity onto the physical aspects of their premises. Logos or brand-specific motifs can be incorporated into the metalwork to create a strong visual identity.

- Branding Elements:

- Logos: Precise cuts for detailed logo reproduction

- Motifs: Repeating patterns that evoke brand imagery

Technical Considerations

When undertaking a custom perforated metal sheeting project, attention to detail is paramount. Precision, technique, and quality control are the cornerstones of a successful perforation job.

Precision in Perforation

In custom perforated metal sheeting, precision is crucial. Tolerances should be defined clearly, and the perforation size, pitch, and pattern must be consistent across the entire metal sheet. The minimum hole size should typically be equal to the material thickness, while the spacing or pitch of the holes should be at least 1.5 times the material thickness to maintain structural integrity.

Machinery and Techniques

Perforating metal requires specialized machinery. The use of CNC punch presses or laser cutters ensures repeatability and precision. The choice between mechanical and laser methods depends on the sheet metal’s thickness, desired hole size, and perforation pattern. For example, lasers are preferred for intricate designs, while punch presses are suited for larger runs of standard patterns.

Quality Control Measures

Quality control is essential to ensure that the perforated sheet metal meets the required specifications and standards. Measures include:

- Visual inspection: To check for consistency and accuracy of the perforation.

- Go/no-go gauges: To test the dimensions of the perforations against the specifications.

- Regular maintenance of machinery: To prevent defects due to wear or misalignment.

Careful oversight at each stage of production mitigates the risk of errors and ensures high-quality outcomes.