Last Updated on June 3, 2025 by Nasir Hanif

In the world of industrial machinery, ensuring that components are properly aligned is crucial for maximizing efficiency and minimizing wear and tear. Misalignment can lead to a host of problems, including increased energy consumption, premature equipment failure, and costly downtime. This article explores the significance of alignment in machinery performance, focusing on the benefits of laser alignment as an effective solution.

Table of Contents

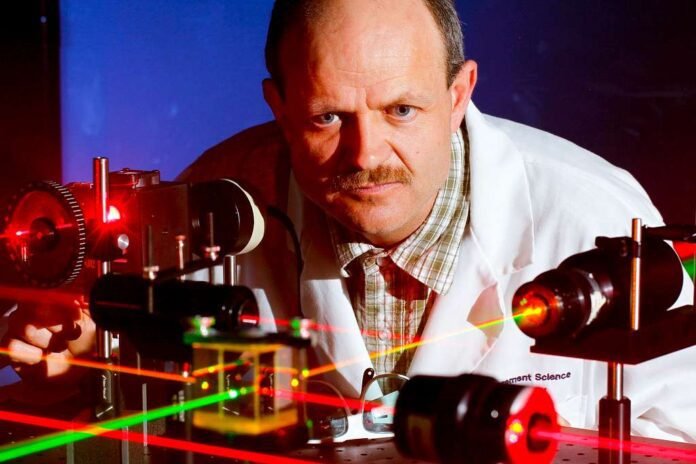

What is Laser Alignment?

Laser alignment is a precision method used to align shafts, couplings, and other mechanical components. Unlike traditional alignment methods, which rely on visual inspection or mechanical tools, laser alignment utilizes laser technology to provide accurate measurements of angular and parallel misalignment. This high level of precision allows for adjustments that can significantly enhance the performance and lifespan of machinery.

Why Alignment Matters

1. Enhancing Operational Efficiency

Proper alignment is essential for the smooth operation of machinery. When components are misaligned, the energy required to operate the equipment increases. This can lead to inefficiencies that not only waste energy but also result in higher operational costs. By ensuring that machinery is correctly aligned, businesses can optimize their processes and improve overall productivity.

2. Reducing Wear and Tear

Misalignment places unnecessary stress on mechanical components, leading to accelerated wear and tear. For instance, if two shafts are not aligned correctly, the bearings may experience uneven load distribution, causing them to fail prematurely. Regular alignment checks, particularly using advanced methods like laser alignment, can help extend the life of machinery and reduce maintenance costs.

3. Minimizing Downtime

Downtime is one of the most significant challenges faced by manufacturing and industrial operations. When machinery fails, it can halt production and result in substantial financial losses. Regular alignment checks and maintenance can prevent unexpected failures by identifying potential issues before they escalate. Implementing a laser alignment program can significantly reduce the risk of breakdowns, ensuring that machinery remains operational and efficient.

4. Improving Product Quality

In industries where precision is critical, such as manufacturing and assembly, misalignment can lead to defects in products. For example, if machinery is not aligned correctly, it can result in uneven cuts or imprecise measurements. This not only affects the quality of the final product but can also lead to increased waste and rework. By ensuring proper alignment through laser technology, companies can maintain high standards of quality in their production processes.

Key Benefits of Laser Alignment

1. Precision and Accuracy

One of the most significant advantages of laser alignment is its precision. Traditional methods can be subject to human error and may not provide the level of accuracy needed for modern machinery. Laser systems, on the other hand, provide real-time data and high-resolution measurements, ensuring that alignment adjustments are made with utmost accuracy.

2. Time Efficiency

Laser alignment is often faster than traditional methods. With the ability to measure and adjust alignment quickly, maintenance teams can complete tasks in a fraction of the time, reducing labor costs and minimizing disruption to operations. This time efficiency is particularly beneficial in environments where every minute of downtime counts.

3. Ease of Use

Modern laser alignment tools are designed with user-friendliness in mind. Many systems offer intuitive interfaces and clear instructions, allowing technicians to operate them with minimal training. This accessibility means that even less experienced staff can conduct alignment checks and adjustments, further enhancing productivity.

4. Versatility

Laser alignment systems can be used on a wide range of machinery, from small pumps to large turbines. This versatility makes them an excellent investment for various industries, including manufacturing, energy, and transportation. By implementing laser alignment across multiple machines, organizations can standardize their maintenance processes and improve overall efficiency.

Implementing a Laser Alignment Program

1. Assess Your Equipment

Before implementing a laser alignment program, it is crucial to assess your machinery and identify which components require regular alignment checks. Consider the types of equipment you operate, the frequency of use, and the potential impact of misalignment on performance.

2. Invest in Quality Equipment

Investing in high-quality laser alignment tools is essential for achieving optimal results. Look for systems that offer durability, accuracy, and ease of use. Many manufacturers offer various options, so choose one that best fits your organization’s needs and budget.

3. Train Your Staff

Proper training is vital for maximizing the benefits of laser alignment technology. Ensure that your maintenance team is adequately trained in using the equipment and understanding the importance of alignment. This knowledge will empower them to perform regular checks and make necessary adjustments, ultimately leading to improved machinery performance.

4. Schedule Regular Maintenance

Establish a regular maintenance schedule that includes alignment checks. Depending on the machinery and operational demands, this could range from weekly to monthly inspections. Consistent monitoring will help identify misalignment issues early and keep your equipment running smoothly.

Conclusion

In conclusion, understanding the importance of proper alignment in machinery is essential for maintaining optimal performance. Implementing a laser alignment program can enhance efficiency, reduce wear and tear, minimize downtime, and improve product quality. By investing in quality equipment, training staff, and scheduling regular maintenance, organizations can reap the benefits of laser alignment and ensure their machinery operates at its best.

By prioritizing alignment in your maintenance strategies, you can safeguard your investments and position your organization for long-term success. Embracing the advancements in laser alignment technology is a step toward achieving optimal machinery performance and sustaining operational excellence.