Last Updated on January 15, 2026 by Rida Gul

There are a variety of uses for filter fabrics. These include dust removal and the removal of particulates in a gas stream. There are also high-temperature end-uses. Nonwoven filtration fabrics are the most lucrative segment of the nonwoven industry. This market is undergoing a lot of consolidation, with many companies acquiring smaller competitors.

Table of Contents

Wetland glass fabric

Wetland glass fabric is woven glass primarily used for high-temperature applications. The unique characteristics of wet-laid glass fabric allow it to be used in various industrial filtration solutions. These advantages include flexibility in fiber blending and the ability to tailor a product to multiple applications. One of these applications is biodegradable cover sheets for agricultural use.

Multifilament filter cloth

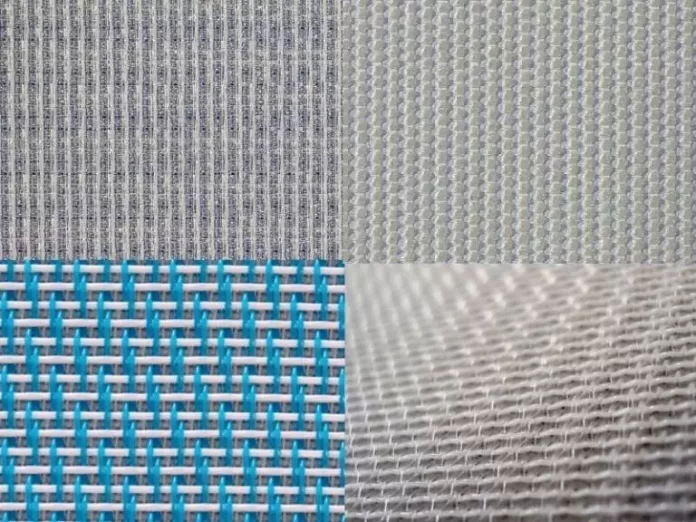

Multifilament filter cloth is made from polymer yarns and filters liquids and gases. The fabric’s density and size depend on the type of particulate it is designed to capture. It is used in industrial filtration solutions to remove particles as small as 20 microns. It is also used in medical applications, including open-heart surgery filters. Other applications include automotive transmission filters and air conditioning filters. It is also used in grain and flour processing processes and as a sludge dewatering belt. Filter cloths are often made from several materials, including polyester. Polyester multifilament has superior tensile strength, allowing it to last longer than regular polyester filter felt. Fiberglass felt is an excellent choice for high-temperature filtering, while acrylic felt is suitable for temperatures below 130 degrees Celsius. Multifilament filter cloth is also available in multi-fiber construction, which combines PET, PPS, and acrylic fibers into one filter.

Warp-knitted filter cloth

The use of warp-knitted filter cloth in industrial filtration systems is increasing. These fabrics are made from multifilament fibers designed to capture fine particles. The material is made from many threads, including cellulosic and synthetic blends. Warp yarns are placed longitudinally on the fabric, and the weft yarns pass through the width of the warp. This creates a space between the warp and weft threads known as the mesh opening. The distance between these threads is measured in millimeters or inches. Different yarn sizes are also available. The diameters of the yarns determine how many open spaces are present in the fabric, which affects the amount of filtration.

Warp-knitted filter cloth offers several advantages for the construction of industrial filtration systems. Its low weight and technical properties make it more economical than woven fabrics. In addition, its density enables engineers to repair damaged sections of pipes without extensive excavation, allowing the system to be returned to use in a short time.

Vinylon filter cloth

Vinylon filter cloth is a type of high-quality filtration material. It has outstanding abrasion resistance and permeability, as well as good resistance to acids and alkalis. The material is also highly resistant to wear and tear and has a long service life. As a result, it is suitable for use in various applications, including food, rubber, and metallurgical processes.

Vinylon filter cloth is an industrial filter cloth with a hydrophobic surface that resists blockage. The filter cloth is available in various materials, including cotton, nylon, and polypropylene.

Dust removal in fabric filters

Fabric filters are designed to remove fine particles from the air. They are composed of a tank, a filtration chamber, a deflector device, and a control system. During operation, the process air flows through the filtration chamber, and clean air exits the filter. A filtration system controls the filtration process by varying the pressure of the air flowing through it. Fabric filters are commonly used in industrial applications for removing particulate matter. The process is similar to that of sand filters. Dust particles adhere to the fabric because of surface force and are brought into contact with the filter by Brownian diffusion or impingement. This filter is a much more efficient collector of sub-micron particles than traditional methods.

Removal of particulates from a gas stream

One industrial use of filter fabrics is to remove particulates from a gas stream. This process is also known as pulse jet bag filtration. Its operation is based on the inertia separation principle. The particulates in the gas stream collect on the surface of the filter bag, which is then pulsated by air to dislodge them. They then fall into the bottom of the industrial bag filter. The process repeats until the filter bag is clean. Filter fabrics are usually made from a nonwoven material. The nonwoven fabric has multiple layers and is supported by a woven backing. The woven filter is generally used for high-energy cleaning, while felted fabrics are better suited for lower-energy cleaning methods. Both types of filters can be manufactured with different weaving patterns. The filter fabric’s weave affects the filter’s strength, while the space between the fibers influences its permeability—a tighter weave results in a more robust filter that captures finer particles.

High-temperature end-uses

High-temperature filter fabrics have many uses, from everyday products like oven liners to high-tech industrial processes. These materials can handle various temperatures, making them indispensable for these applications. Furthermore, high-temperature filter fabrics can be classified according to their temperature range, so selecting the suitable material for your application is not complicated.

Filter fabrics tested for their high-temperature capabilities include reverse-air baghouses used in cement kilns and smelters and textile and food manufacturing facilities. Filter fabrics that can resist high temperatures can be used in these applications because they are more heat-resistant than other fabrics.

Advancements in Multifilament Filter Cloth Technology

Multifilament filter cloth has emerged as a pivotal component in diverse industrial filtration systems, showcasing remarkable versatility in capturing particles across liquids and gases. With a focus on enhancing filtration efficiency, recent advancements have led to the development of multifilament fabrics capable of capturing particles as small as 20 microns. These innovations extend beyond conventional industrial applications, finding utility in critical medical procedures such as open-heart surgery filters. Moreover, the incorporation of diverse materials like polyester, fiberglass, and acrylic fibers underscores the adaptability of multifilament filter cloth to varying temperature ranges and operational demands. As industries continue to prioritize filtration performance, the evolution of multifilament filter cloth remains integral to meeting stringent quality standards and ensuring optimal operational outcomes.

Apart from this, if you are interested to know about Stealth 600 Gen 2 Review then visit our Technology category.