Last Updated on February 9, 2025 by Bisma Sehar

PEEK Plastic, ULTEM 2300, PEEK machining for over 25 years, PEEK Plastics has been a leader in providing high-quality materials and applications expertise to customers worldwide. The company has maintained ISO 9001 certification since 1996, ensuring that the quality of each PEEK material product is consistent with the stringent requirements of the industry.

In this article, you will learn what is PEEK, is the difference between ULTEM 2300 and PEEK, why a PEEK material is one of the strongest thermoplastic materials on the modern market. You’ll also find out about the machining of this material. Here There are 12 types of plastics that can be distinguished. They’re based on the amount of carbon, hydrogen, and oxygen in their composition.

Table of Contents

The Advantages of PEEK

There are many advantages of PEEK plastic. It is a semi-crystalline polymer that is very durable and has good chemical-resistant properties. It holds up well under stress to produce excellent material for the medical industry and plastic surgery applications. Natural PEEK plastic sheet is used in implants, catheters, sutures, and prosthetics. The material also has a high melting point which means it can be used where extreme heat is present.

PEEK plastics are also used in the automotive industry for vacuum-formed parts like dashboards and in the HVAC industry for air ducting and insulation. The material has been proven to last long without degrading and is highly resistant to wear and tear.

PEEK is stronger and more heat resistant than many other plastics. The material has a modulus of elasticity of over 200 ksi, making it much stiffer than Nylon, Ultem, or Delrin. PEEK is also very durable and difficult to break, even under extreme temperatures.

ULTEM 2300 plastic

Currently, PEEK and ULTEM are the two most popular engineering plastics. PEEK is more expensive than ULTEM, but it’s also stronger and more resistant to extreme temperatures. Both materials are thermosetting polymers that can be molded into a variety of parts and products.

Ultem® resins are the engineering resins that have set the standard for engineering plastics. From vacuum parts to housings under pressure and exposure to harsh environments, Ultem resins have been used successfully by engineers around the world for decades. These materials are used in demanding applications such as medical devices and pharmaceutical equipment where they must endure extreme temperatures, corrosive chemicals, or sterilization cycles.

In fact, The polymer Ultem 2300 rod is used in many of the same applications as PEEK. The major difference between the two is their resistance to heat. While both materials can withstand high temperatures in industrial applications, they differ in other applications or settings.

ULTEM weighs less than half as much as carbon fiber, making it an ideal material for lightweight designs that need to maintain strength without adding excess weight. It’s also an excellent material for use in high-impact products such as gears that endure high levels of stress.

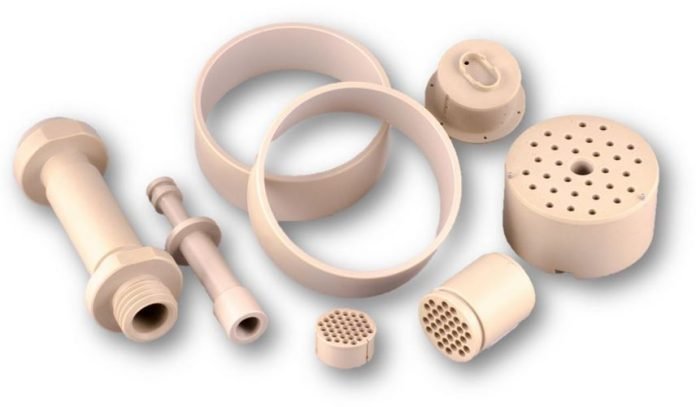

PEEK Machining

A lot of people and companies do not know much about PEEK Plastics or how it can be used for anything, but the fact is that it can be used for a lot of things. This particular material is very versatile and can be used for many purposes. Let us take a look at what it can be used for and how to do PEEK Machining. By the way, if you want to find a good machining partner, you need a China PEEK machining service.

PEEK is an engineering thermoplastic with high strength and excellent heat/chemical resistance properties. It is widely used in medical and industrial applications where its unique combination of properties makes it the material of choice.

PEEK has been proven over many years in demanding applications such as implantable medical devices, electronic connectors, and aerospace components.

Read More: Tips For Leading A Successful Team