Last Updated on February 13, 2025 by Bisma Sehar

It’s said that the Boeing 787 Dreamliner airplane utilizes 30 3D printed parts, which sets the industry record. Moreover, recently it was announced that General Electric will invest $50 million into developing fuel nozzles for the new generation of LEAP jet engines. The main reason for the growing interest in the aerospace industry in 3D printing technologies lies in the ability to produce a significantly bigger number of lightweight parts. According to the representatives of American Airlines, reducing an airplane weight by 500 grams can save more than 40 thousand liters of fuel annually.

Vivek Saxena, vice president of aerospace operations and supply chain at ICF International – a company that provides technical consulting, – says that 3D printing accounts for 0.0002% of the global manufacturing market, Regarding the aerospace industry, 3D printing accounts for 0.002% of a $150 billion market. Saxena agrees with the opinion held by various experts that the size of the 3D printed parts market will reach $2 billion during the next decade. Considering these prospects, the potential ways of using the technology look even more ambitious. Below is the list of the most promising ways of implementing 3D printing in aerospace production.

Table of Contents

Aircraft Wings

Taking into consideration that relatively small aircraft parts are already produced using 3D printers, Boeing finds it possible to print a whole wing. At this stage of the development of 3D printing technologies producing large-sized objects is limited in some ways, since with growing dimensions internal stress also increases and might cause some deformations. But a new product by BAE Systems allows for producing reinforced metal parts by treating each layer with ultrasound waves. This reduces stress which will make 3D printing large objects such as aircraft wings possible in the future.

Complex Engine Parts

Apart from 3D printing fuel nozzles, General Electrics is also actively developing a way to 3D print parts of the largest jet engine in the world: the GE9X, which will power the next generation of the passenger airplanes Boeing 777X. 3D printing technologies can also be useful for experimental prototyping in order to test technical specifications without spending huge amounts of money on CNC equipment. 3D printing a life-sized turboprop engine as a part of the new collaboration by Autodesk and Stratasys showed how promising using 3D printing for producing jet engines is.

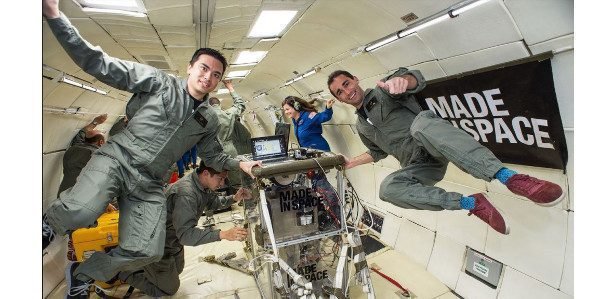

Space Manufacturing

Today, NASA spacecraft includes about 70 3D printed parts but all of them are produced on the Earth which complicates the supply chain and extends the required time. Manufacturing the parts in space would significantly cut the costs and simplify the planning without the need to send a rocket with the required tools and parts in space. 3D manufacturing in space is an area that’s actively investigated by such research groups as Made in Space and Lunar Buildings. Working with NASA, Made in Space conducts the experiments in zero-G, testing the possibilities of using 3D printing on the ISS for manufacturing the required parts and tools

Unmanned Aerial Vehicles

BAE Systems recently announced that their 2040 developed engineering concepts for aircraft include the equipment that can be used for manufacturing unmanned aerial vehicles using 3D printers aboard an aircraft. The idea is that the aircraft coming to the crash site will assess the situation and then send some information to a data center. Data will then be fed to the 3D printers on board, which will print the drones required for the situation. These aerial vehicles will be able to monitor the situation or even go on rescue missions. While the concept is still under development, the BAE system has already invested $180 million into it

3D Printing as a Service (3DPaaS)

NASA is researching using 3D printing as a service for rapid pre-prototyping. “3D printing makes it easier to capture the imagination of the mission concepts. We can see what others are imagining.”, explains Tom Soderstrom, IT chief technology officer at NASA Jet Propulsion Laboratory. Using 3DPaaS will help the engineers to receive peer reviews, alternate design solutions, as well as a prototype’s approval. Moreover, this technology will help attract external specialists with original ideas, which will reduce both the costs and times of development.

Apart from that if you want to know about List of Suppliers Countries Across the Globe then please visit our Technology category.