Last Updated on February 16, 2024 by Saira Farman

3D printing (which is also called “additive manufacturing”) is a process of making a three-dimensional or 3D object (layer-by-layer) by using a computer-generated design. In this 3D printing process, a physical object or thing is manufactured from a digital format by printing thin layers of resources and fusing them. Here we will discuss importance of 3D printing technology.

When 3D printing technology was introduced, it unimaginably enhanced manufacturing productivity. The significant fact about 3D printing is that people can make intricate or complex shapes using less material than traditional manufacturing processes.

With this 3D printing process, prototypes can be made more accessible, faster, and cheaper. It also allows for many things such as –

- more innovation

- experimentation

- product-based startups (etc.)

Table of Contents

What is Meant by 3D Printing?

3D printing is a process of making three-dimensional solid objects from a digital file. The creation of a 3D printed object is achieved using additive processes. In an additive process, an object is created by successively adding material layer by layer. 3D printing is the opposite of subtractive manufacturing, which involves taking away material until you have the desired shape.

3D printers come in many different shapes and sizes, but all use the same basic principle: they lay down successive layers of material until the entire object is created. That said, there are several different types of 3D printing technology, each with its own advantages and disadvantages.

The most common type of 3D printer is the dual extruder 3D printer. These printers have two nozzles that can print two different colors or two different materials. This allows for greater flexibility when it comes to what you can print. However, dual extruder printers are usually more expensive than single nozzle printers.

3D printing is a versatile technology that can be used to create a wide variety of objects. The key to success with 3D printing is to find the right printer for your needs and to understand the limitations of the technology. With careful planning and execution, you can use 3D printing to create just about anything you can imagine.

3D Printing Software

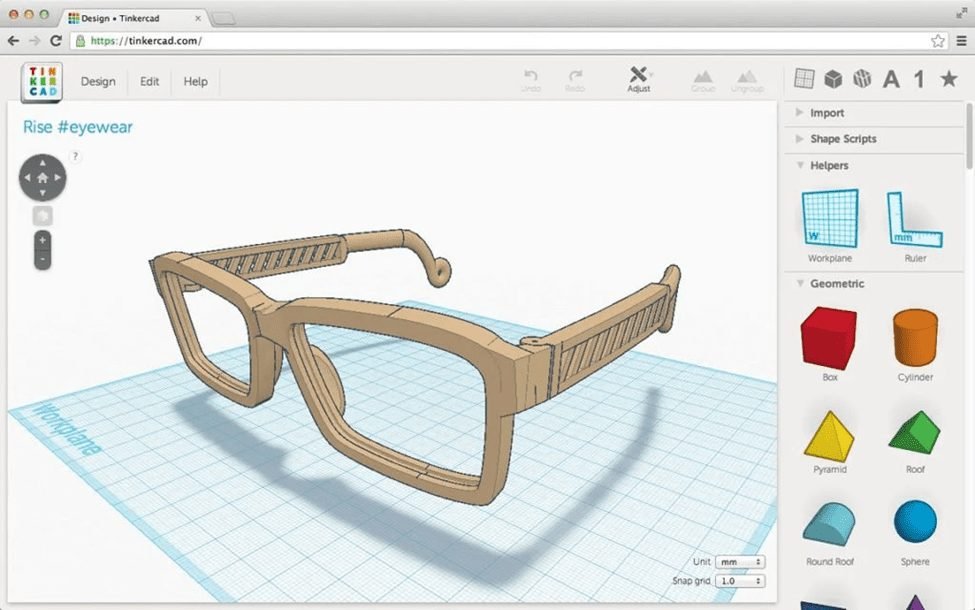

3D model created using a 3D software. Image source: 3D printing

For 3D printing, individuals need excellent 3D printing software that makes every design simple and easy. Design made with 3D printing software is more efficient and user-friendly. The 3D printing software can make people’s dreams about bringing their imaginations to reality.

With 3D printing software, advanced programs could be a great asset, as they offer unique as well as amazing possibilities. Professionals also could use these programs to get unique 3D models to 3D print and prototype or produce their project. A good example of a 3D printing software is SelfCAD. SelfCAD is a free CAD software that allows users to model, sculpt, and even slice their designs all under one program without the need for an additional software.

These 3D printing services can readily design for FDM and DLP Printers.

There are many important aspects of 3D printing. Here we discuss the top 5 importance of these processes –

1) Speed up design process and production

One of the vital importance of 3D printing technology is rapid manufacturing, which is essential to increase the designing process. Moreover, design can be easily changed without affecting the speed of the production process.

With these advanced 3D printing techniques, a business can be designed in-house based on a professional 3D printer within a few days. Depending on an objects’ design and complexity, 3D printing can print things within just a few hours.

The manufacture of them can offer time savings through 3D printing. The design process can be pretty fast by making CAD or SLT files ready to be printed.

2) Cost-Effective

In small production houses and run applications, only the 3D printing method is the most cost-effective manufacturing process. It is that kind of manufacturing process, which saves a lot of time and hence the costs connected with using different machines for manufacture.

3D printing materials can be a little expensive to purchase, but an option is to avoid this cost by outsourcing their project to a 3D printing service company. Less waste material is generated because the object is built from the ground level & not carved out of a solid block as in traditional manufacturing.

3) Reducing amount of waste with additive production

In several industries, many objects are built using 3D printing processes. The biggest problem with industrial manufacturing is a lot of waste generated during the process. But with the 3D printing method, the amount will be reduced.

Metal shavings need to be collected, cleaned, and recycled, which is a long process & this method requires both time and cost. But the modern 3D printing method reduces much of this clean-up, saving time and waste.

4) Lightweight & strong parts

The main material of 3D printing with used elements includes plastic, though few metals can also be used for 3D printing. Plastics provide benefits as they are lighter than their metal identical.

This is especially important in companies such as – aerospace & automotive where light-weighting is an issue. 3D printing can solve this issue & also can deliver greater fuel efficiency.

Apart from all of this, objects can be created from tailored materials to offer some specific properties such as –

- heat resistance

- higher strength

- water repellency (etc.)

5) Print on multiple demands

One of the critical aspects of 3D printing is that it can print objects on multiple demands, which does not need much space to stock inventory, unlike traditional production processes. Unless required, there is no need to print in bulk. 3D printing saves space and costs.

The 3D design files are all stored in a virtual library because they are printed using a 3D printing process. The design can be located and printed when needed. This way, people can use it multiple times on their demand.

Besides, all of that edits to printing designs can be done at minimum costs by editing people’s files without wasting out-of-date estimates and investing in tools.

Wrapping up

The main point is product life cycles are reduced because of the speed and minimum costs of 3D printing. Industries can develop and increase product quality, delivering better products quickly.

Instead of leaving it to their imaginations, 3D printing services offer the physical demonstration of a new build product to customers and investors.

One of the other essential information is that the 3D printing process also allows their users for cost-effective market testing, as well as presence feedback from dynamic customers and, after that, investors on an actual product.